How do you stack disc springs?

The potential combinations of disc springs depend on function and desired force.

Having springs working in tandem is always a challenge, but not when it comes to disc springs.

This type of spring is designed to work together, and the potential combinations for disc springs depend entirely upon the project.

It is extremely important to ensure accuracy in stacking the disc springs. You can do it using either the inside diameter or the outside diameter.

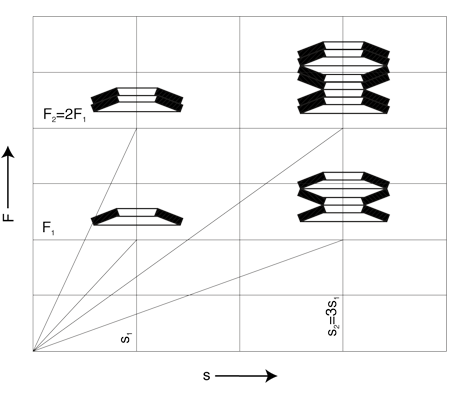

When you stack disc springs, the spring constant, force and travel are changed, depending on the combination.

Single

Normal force, normal travel

Parallel

greater force, normal travel

Series

Normal force, longer travel

Series-Parallel

greater force, longer travel

Which type of disc spring stacking - should I choose?

It depends what you want to get out of your stacking:

- Parallel stacking: Gives greater force - 1 times travel but x times force depending on the number of disc springs on top of one another.

- Series stacking: Gives more travel - 1 times force but x times travel depending on the number of disc springs set against one another.

In series-parallel stacking, there must never be a difference in the number of disc springs per bundle. If a bundle has 1 disc spring less than the other bundles, this bundle will naturally not have the same strength, and will therefore become deformed and broken before the other bundles.

You can expect a loss of force when you use several disc springs together in parallel stacking due to the friction.